Table of Contents

ToggleIn the bustling world of workshops, where creativity meets machinery, proper ventilation isn’t just a luxury—it’s a necessity. Picture this: a craftsman diligently chiseling away at a masterpiece, only to be interrupted by a cloud of sawdust that could rival a winter storm. Not exactly the ideal work environment, right? Effective ventilation keeps the air fresh and the creativity flowing, ensuring that inspiration isn’t stifled by stale air or pesky fumes.

But let’s be real—ventilation isn’t just about comfort; it’s about safety too. Poor air quality can lead to headaches, fatigue, and even long-term health issues. So, whether you’re a hobbyist or a seasoned pro, understanding workshop ventilation can save the day (and your lungs). Dive into the essentials of creating a breath of fresh air in your workspace and discover how to keep both your projects and your well-being in top shape.

Importance Of Workshop Ventilation

Proper workshop ventilation ensures creativity and safety by enhancing air quality. Inadequate airflow leads to discomfort and health risks, including headaches, fatigue, and respiratory problems. Fresh air circulation reduces harmful fumes from paints, adhesives, and other materials. Regular ventilation strategies minimize dust and particulates, improving overall working conditions.

Healthy air promotes focus and efficiency in a workshop setting. When ambient air quality remains high, individuals experience fewer distractions and greater productivity. Safety also becomes a priority as proper ventilation prevents the accumulation of toxic substances. Workshops that prioritize air movement maintain an environment conducive to creativity and innovation.

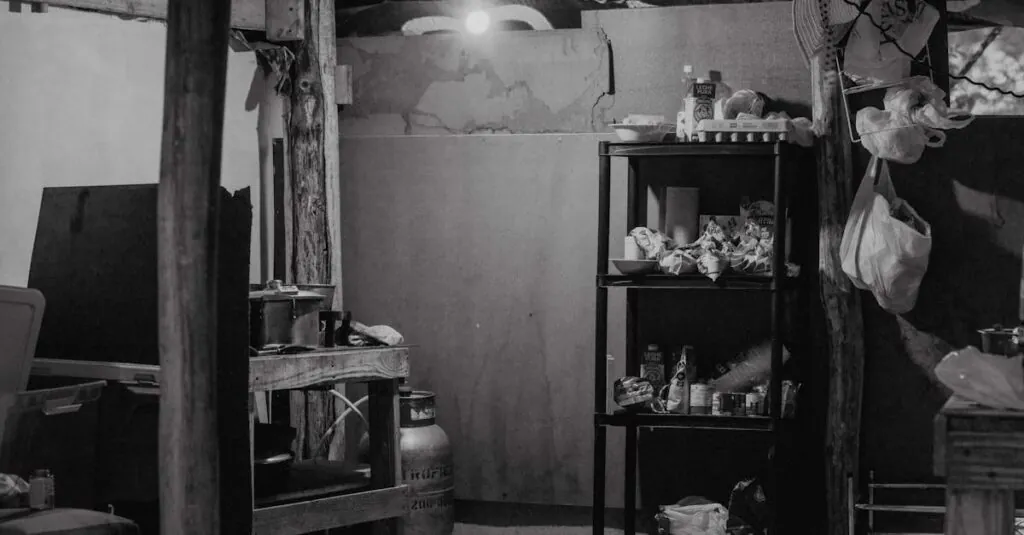

Implementing effective ventilation systems requires consideration of workshop size and layout. Exhaust fans, open windows, and air filtration units contribute to an optimal indoor climate. A well-ventilated workshop supports compliance with occupational health regulations. This practice safeguards workers against long-term health complications associated with poor air quality.

Periodic evaluation of air circulation helps identify areas for improvement. Workshops can benefit from installing additional ventilation points or updating existing systems. Active monitoring ensures that the air remains clean and fresh throughout the workday. By prioritizing workshop ventilation, individuals cultivate a safer, more inspiring workspace.

Types Of Workshop Ventilation Systems

Various workshop ventilation systems enhance air quality and ensure a safe working environment. Understanding the options available helps users make informed choices.

Natural Ventilation

Natural ventilation relies on ambient airflow and can be an effective solution for many workshops. Open windows and vents permit fresh air to enter while allowing stale air to exit. This system works best in environments with adequate outdoor airflow. It reduces energy costs since it doesn’t require power for operation. Regularly adjusting openings optimizes air circulation. Moreover, integrating skylights can improve lighting alongside ventilation. However, it’s crucial to consider weather conditions, as natural systems might be less effective during extreme temperatures.

Mechanical Ventilation

Mechanical ventilation systems use fans and blowers to control air exchange actively. Ducted exhaust systems draw out contaminated air, reducing hazardous fumes and lingering odors. Typical setups include ceiling or wall-mounted fans to improve airflow. Combustion appliances like gas heaters also require efficient exhaust to prevent toxic buildup. Several models offer filtration options that trap particles and allergens, enhancing air quality. Regular maintenance ensures these systems work effectively and efficiently. Assessing the workshop’s size and layout ensures suitable placement for maximal air movement.

Factors Affecting Workshop Ventilation

Several key factors influence effective workshop ventilation. Understanding these elements ensures optimal air quality and comfort in the workspace.

Space Size and Layout

Space size directly impacts airflow dynamics. Smaller workshops may rely on fewer ventilation points, whereas larger spaces often require a more comprehensive system. Layout also plays a critical role; the arrangement of equipment can obstruct air movement. Open areas allow for better circulation while compact workstations may hinder air exchange. To maximize efficiency, he or she must position ventilation units away from obstructions. Evaluating the workshop’s dimensions and design enhances the effectiveness of ventilation solutions.

Equipment and Processes

Different tools and processes generate varying levels of contaminants. Heavy machinery often produces significant exhaust and dust, demanding stronger ventilation strategies. Smaller processes, like painting, may release VOCs that necessitate targeted air filtration systems. Identifying these sources allows for tailored solutions, ensuring effective removal of harmful particles. Regular assessment of operational activities helps in adapting ventilation systems to dynamic workshop needs. Prioritizing equipment and processes not only improves air quality but also enhances overall workplace safety and productivity.

Benefits Of Proper Workshop Ventilation

Proper workshop ventilation significantly enhances air quality in the workspace. Improved air quality reduces harmful fumes from materials such as paints and adhesives. Healthier air creates a more enjoyable environment for creative work, allowing individuals to focus better. Increased concentration leads to greater productivity, minimizing distractions often caused by poor air conditions.

Safety remains a crucial aspect of effective ventilation. With proper airflow, the risk of toxic substance accumulation decreases. Workshops that prioritize ventilation help protect not only physical health but also overall well-being. Compliance with occupational health regulations is essential for maintaining safe work environments, especially when specific materials or processes are involved.

Consideration of workshop size and layout strengthens the effectiveness of ventilation systems. Smaller workshops can often utilize fewer ventilation points. In contrast, larger spaces may need comprehensive systems to ensure proper air circulation. Placing ventilation units away from obstructions maximizes airflow efficiency.

In addition, tailored ventilation strategies are necessary for various tools and processes. Different tools generate varying levels of contaminants, influencing the required ventilation design. Regular assessments of operational activities help adjust systems to meet the dynamic needs of the workshop. Adaptations ensure effective removal of harmful particles, enhancing safety and productivity simultaneously.

Ultimately, prioritizing proper workshop ventilation fosters an inspiring and healthy work environment. Implementing effective strategies encourages creativity and innovation while maintaining safety.

Common Challenges In Workshop Ventilation

Inadequate airflow poses significant challenges in workshop ventilation. This lack of proper exchange leads to poor air quality, resulting in discomfort and health issues such as headaches and fatigue. Moreover, it can prevent effective removal of harmful fumes from paints and adhesives, compromising safety.

Another challenge arises from varying workshop sizes and layouts. Smaller workshops might manage with basic ventilation, but larger spaces often require more complex systems. Equipment arrangement also plays a critical role; if machines block airflow, ventilation effectiveness decreases.

Dust and particulates create further complications. Certain tools generate high levels of dust, necessitating tailored strategies for effective removal. Regular assessment of these factors is vital to adapt ventilation systems to changing conditions and ensure optimal air quality.

Extreme weather conditions can also affect natural ventilation systems. Relying solely on ambient airflow may not provide sufficient exchange when windows and vents cannot operate effectively. This limitation emphasizes the importance of integrating mechanical systems, which actively manage air quality.

Maintenance of ventilation systems represents another challenge. Regular checks ensure that exhaust fans and air filtration units operate efficiently. Users often overlook this aspect, leading to diminished performance over time.

Complying with occupational health regulations adds another layer of complexity. Workshop owners must understand specific requirements for ventilating spaces to prevent toxic substance accumulation. Prioritizing these elements contributes to a healthier and more productive work environment.

Effective workshop ventilation is essential for maintaining a safe and productive environment. By ensuring proper air quality, individuals can enhance their focus and creativity while minimizing health risks associated with poor ventilation.

Implementing the right ventilation strategies tailored to specific workshop needs can significantly improve overall air circulation. Regular assessments and maintenance of ventilation systems are crucial to adapt to changing conditions and ensure optimal performance.

Prioritizing ventilation not only meets safety regulations but also fosters an atmosphere where innovation can thrive. A well-ventilated workshop is a foundation for success, empowering both hobbyists and professionals to work efficiently and safely.